Hydrated Lime Powder

Hydrated Lime Powder Specification

- Product Type

- Hydraulic Lime

- Material

- Limestone

- Application

- Desiccant

- Size

- Customized

Hydrated Lime Powder Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- Kilograms

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Packaging Details

- 40 to 50kg bag

- Main Domestic Market

- All India

About Hydrated Lime Powder

Creating content about white quick lime powder involves highlighting its properties uses production process and safety considerations Heres a structured outline to develop informative content

Introduction to White Quick Lime Powder

White quick lime powder also known as calcium oxide CaO is a versatile chemical compound widely used across several industries for its various properties and applications

Characteristics

Appearance White quick lime powder is a fine white odorless powder with high alkalinity

Chemical Composition It is primarily composed of calcium oxide CaO derived from heating limestone or calcium carbonate to high temperatures

Reactivity White quick lime powder is highly reactive with water producing heat and converting into calcium hydroxide slaked lime

Production Process

Calcination The production of white quick lime powder involves calcining heating limestone or calcium carbonate at high temperatures around 9001000C This process releases carbon dioxide leaving behind calcium oxide

Purification The resulting calcium oxide is then finely ground into a powder ensuring uniform particle size distribution

Applications

Construction White quick lime powder is used in construction for mortar and plaster applications It acts as a binding agent and provides strength and durability to structures

Chemical Industry It serves as a raw material in the chemical industry for the production of calciumbased chemicals such as calcium hydroxide and calcium carbonate

Environmental Applications White quick lime powder is utilized in environmental applications for wastewater treatment flue gas desulfurization and soil stabilization

Metallurgical Industry It is used in the metallurgical industry for fluxing refining and reducing impurities in metals

Safety Considerations

Handling Due to its alkalinity white quick lime powder can cause irritation to the skin eyes and respiratory system Proper handling procedures including the use of protective equipment gloves goggles masks are essential

Storage Store white quick lime powder in dry conditions away from moisture to prevent spontaneous reaction with water

Environmental Impact

Recycling Used lime products can often be recycled or reused in various applications promoting sustainability

Emissions The production of white quick lime powder may generate carbon dioxide emissions but advances in technology aim to reduce environmental impact through efficient kiln designs and energysaving measures

Conclusion

White quick lime powder is a fundamental chemical compound with diverse applications in construction chemical manufacturing environmental remediation and metallurgy Understanding its production process applications safety considerations and environmental impact is crucial for its responsible use across industries

This structured content provides a comprehensive overview of white quick lime powder covering its characteristics production process applications in various industries safety considerations and environmental impact It aims to educate readers on the importance and versatility of this chemical compound in modern industrial and environmental contexts

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 9223331 Kilograms

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lime Powder Category

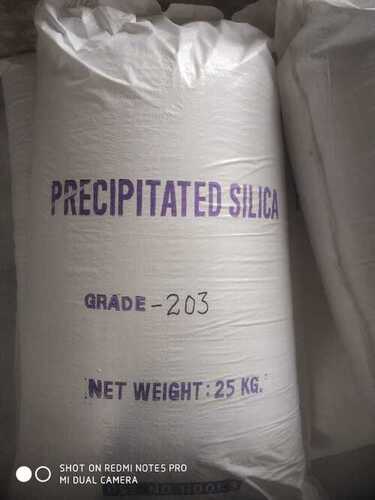

precipitated silica

Price 00 INR / Ton

Minimum Order Quantity : 25 Tons

Product Type : Other, Precipitated Silica

Shape : Powder

Application : Other, Industrial, Rubber, Tyre, Paints, Pharmaceuticals, Cosmetics, Detergent

Packaging Type : HDPE Bag / Paper Bag

Hydrated Lime Powder 80% - 90%

Price 86.0 INR / Ton

Minimum Order Quantity : 25 Tons

Product Type : Other, Chemical Compound

Shape : Powder

Application : Other, Industrial, Water Treatment, Construction, Chemical Manufacturing

Packaging Type : HDPE bags, Jumbo bags

Burnt lime

Price 00 INR / Ton

Minimum Order Quantity : 1000 Tons

Product Type : Other, Burnt Lime

Shape : Other, Lumps or powder

Application : Other, Industrial, water treatment, chemical manufacturing, metallurgy

Packaging Type : HDPE bags, Jumbo bags, or as per customer requirement

CaCO3 calcium carbonate powder manufcaturer

Price 0.1 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Other, CaCO3 calcium carbonate powder manufcaturer

Shape : Powder

Packaging Type : Bag