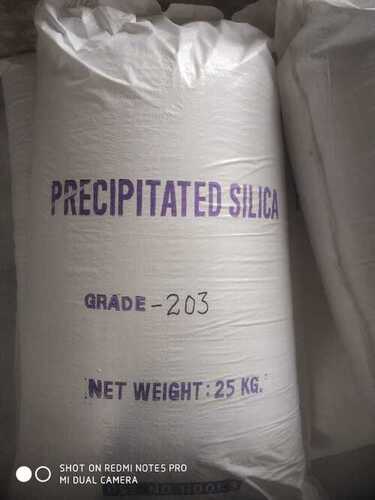

precipitated silica

precipitated silica Trade Information

- Minimum Order Quantity

- 25 Tons

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA)

- Main Domestic Market

- All India

About precipitated silica

Precipitated silica is a versatile form of silica known for its wide range of applications across various industries Heres a structured content outline that covers its characteristics uses production process and environmental considerations

Introduction to Precipitated Silica

Precipitated silica also known as silica dioxide is a synthetic form of silica produced through a chemical process It is valued for its unique properties and finds application in diverse industries due to its versatility and performanceenhancing capabilities

Characteristics

Particle Size and Structure Precipitated silica consists of fine particles with a highly porous structure which contributes to its high surface area and absorptive properties

Chemical Composition Chemically it is composed of silicon dioxide SiO2 with properties that can be tailored during manufacturing to meet specific application requirements

Production Process

Precipitation Method The production of precipitated silica involves the precipitation of soluble silicates from a solution with an acid This process results in the formation of a silica gel which is then further processed to obtain the desired particle size and characteristics

Surface Modification Surface treatment of precipitated silica may include modifications to enhance properties such as dispersibility hydrophobicity or compatibility with various matrices

Applications

Rubber Industry Precipitated silica is extensively used as a reinforcing filler in tires and industrial rubber products It improves abrasion resistance tear strength and reduces rolling resistance in tires

Plastics and Polymers It serves as a reinforcing agent and antiblocking agent in plastics improving mechanical properties scratch resistance and surface finish

Food and Personal Care In the food industry precipitated silica is used as an anticaking agent and viscosity modifier In personal care products it enhances texture absorbency and acts as a thickening agent in formulations

Coatings and Paints It functions as a matting agent anticorrosive additive and improves scratch resistance in coatings and paints

Environmental Considerations

Resource Efficiency Precipitated silica production can utilize silica byproducts and waste materials contributing to resource efficiency and waste reduction

Recyclability Products containing precipitated silica can be designed for recyclability minimizing environmental impact during disposal

Conclusion

Precipitated silica is a multifunctional material with applications spanning industries such as rubber plastics food personal care and coatings Its unique properties production process and environmental benefits make it a valuable ingredient in enhancing product performance and sustainability across diverse sectors

This structured content provides a comprehensive overview of precipitated silica covering its characteristics production process applications across various industries and environmental considerations It aims to inform readers about the importance and versatility of this synthetic silica form in modern industrial applications

Price 00 INR/ Ton

- Minimum Order Quantity

- 25 Tons

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Lime Powder Category

CaCO3 calcium carbonate powder manufcaturer

Price 0.1 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Other, CaCO3 calcium carbonate powder manufcaturer

Shape : Powder

Packaging Type : Bag

white dolomite powder

Price 00 INR / Metric Ton

Minimum Order Quantity : 20

Product Type : Lime Plaster

Packaging Type : bags

Application : Agriculture

Hydrated Lime Powder

Minimum Order Quantity : 100 Kilograms

Product Type : Hydraulic Lime

Shape : White powder

Application : Desiccant